Quality Management

Our Policy of Quality Control

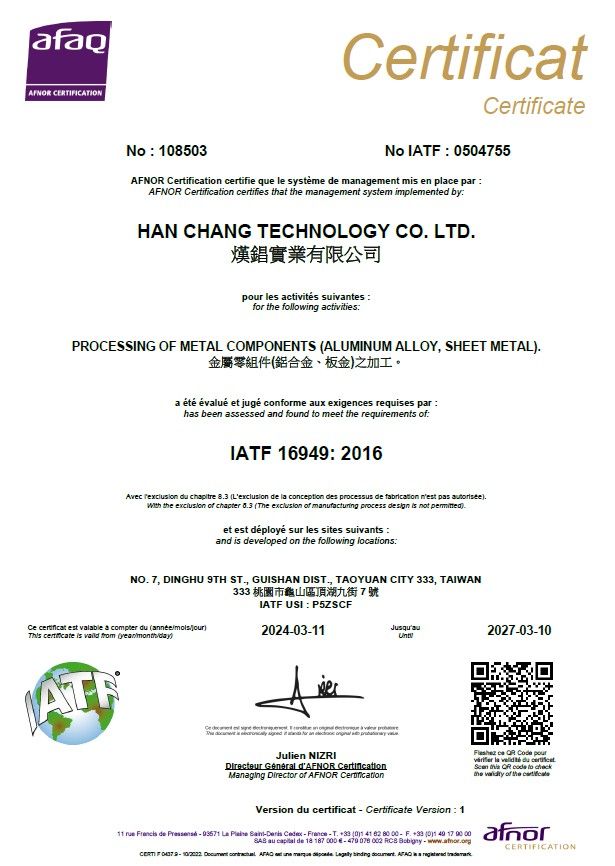

Han Chang always insisting in providing the best quality to our clients. Our production process is aligned to customer needs and our quality chain begins with the first contact with customers and ends with the delivered product. We implemented ISO 9001 since 2005 to ensure we have the ability to produce excellent quality and applying 5S-methodology in our production line from raw-material to semi-finished products. In 2024, we are certificated by IATF16949.

Han Chang certified with ISO 9001 quality management system, ensuring stable and consistent quality in aluminum machining and CNC manufacturing.

Rigorous Quality Inspection

To guarantee every product meets design specifications, we use CMM (Coordinate Measuring Machine) for precise dimensional measurement. Before shipment, we also conduct 100% visual inspections to ensure all surfaces are free from scratches or dents, securing uncompromised product quality.

For packaging, we adopt high-strength corrugated cartons and protective bubble wrap, providing excellent resistance against impact during transportation. For customers with special requirements, we offer customized packaging solutions, ensuring products are delivered safe and damage-free.

- Inspection Equipment

- A device that measures the geometry of physical objects by sensing discrete points on the surface of the object with a probe.

- A measuring device used either for determining the height of objects, or for marking of items to be worked on.

- A measuring device used either for determining the height of objects, or for marking of items to be worked on.

- Provide an accurate flatness for work inspection and for work layout.

- A measuring device of the brightness of a source.

- A measuring device used either for determining the height of objects, or for marking of items to be worked on.

- A device used to measure the distance between two opposite sides of an object.

- Instruments are used for determining surface hardness.

- Used to check the accuracy of measurement instruments and gauge, as well as a size standard for machining parts and mounting tools.

- 3D measurment machine.

- TESA Height gauge.