Aluminum panels machining solution

experience of reducing aluminium machining deformation

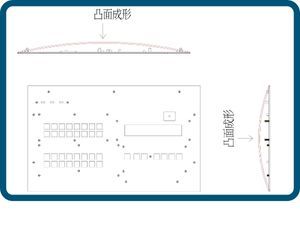

This is a special request from our customer. Normally, panel and frames will be made with a flatmess of 180° degree. However, this customer wants the panel to be spherical. During the process, the first thing we do is to check the flatness upon the arrival of raw material. With CNC vacuum chuck technique the object would better fit on the mold and thus the panel will be made with precise dimension. After CNC machining, the workpiece go through surface finishing process and clinching process. Finally, with our special shaping techniques to make the panel spherical. Our years of experience and skill enable us to understand various process and details. Han Chang's strength is to utilize and integrate all process of aluminium that help our customers overcome the problems that bothers. The case is solved with our professional advice and the product is now a regular order in mass production. Should you have any difficulty or question regarding aluminum processing, please fill out the contact us form and our team of experts will contact you as soon as possible.

Having troubles with aluminium machining?

Give us a chance, Han Chang might be the answers.