Aluminum Extrusions

Unlocking Possibilities: The Advantages of Aluminum Extrusion

Aluminum extrusion is a versatile manufacturing process widely employed across industries. It entails heating aluminum alloy to its softened state and then exerting pressure to extrude it through a shaped opening in a die, resulting in the formation of intricate cross-sectional profiles. The shape of this aperture dictates the final profile of the extruded aluminum. This process enables the production of a variety of complex shapes and sizes to meet diverse industrial needs. Extruded aluminum profiles typically exhibit excellent strength and durability, along with the advantages of being lightweight and recyclable. Here are some advantages of Aluminum extrusion :

- Complex Geometries: Aluminum extrusion allows for the creation of complex cross-sectional shapes and profiles that may be difficult or costly to achieve with other manufacturing processes.

- Cost-Effectiveness: The extrusion process is highly efficient and economical for producing large volumes of aluminum profiles with minimal material waste.

- Lightweight and Strong: Aluminum extrusions offer a favorable strength-to-weight ratio, making them suitable for applications where lightweight yet durable components are required.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, providing inherent corrosion resistance, especially when enhanced through surface treatments like anodizing.

- Design Flexibility: Extruded aluminum profiles can be easily customized in terms of dimensions, tolerances, and surface finishes to meet specific design requirements.

- Recyclability: Aluminum is a highly recyclable material, and extruded profiles can be recycled repeatedly without losing their properties, making the process environmentally sustainable.

- Overall, aluminum extrusion offers versatility, cost-effectiveness, and design flexibility, making it a preferred choice for a wide range of applications across industries such as industrial computing-related products, automotive, construction, aerospace, and consumer electronics.

- Aluminum extrusion processing development process: Custom drawing → Mold analysi → DFM (Design for Manufacturing) → Prototype → Approval → Pilot production → Mass production.

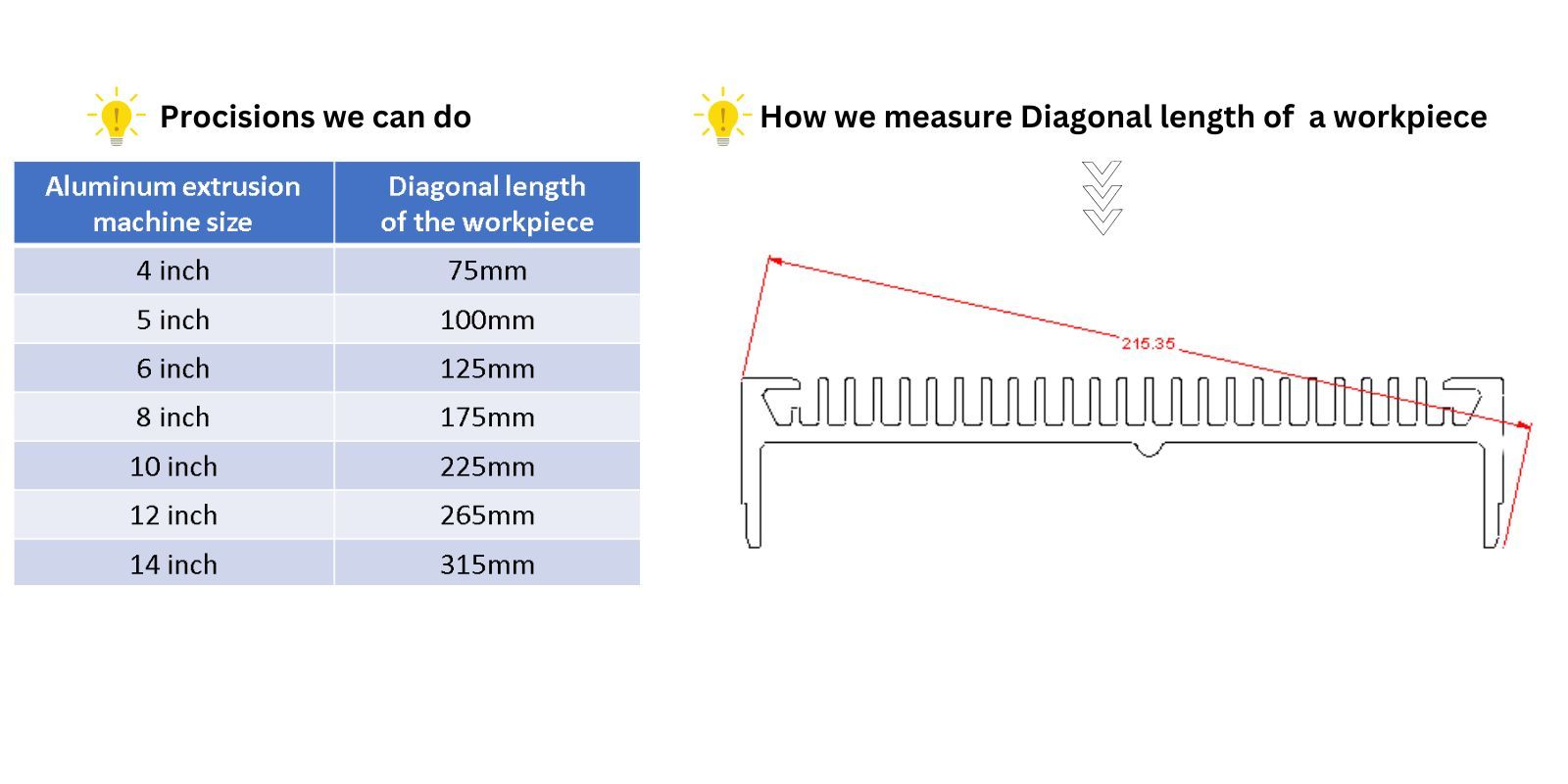

- The following are the workpiece dimensions and extrusion tolerance we can produce.

Workpiece dimensions and extrusion tolerance.

The following are the workpiece dimensions and extrusion tolerance we can produce. :