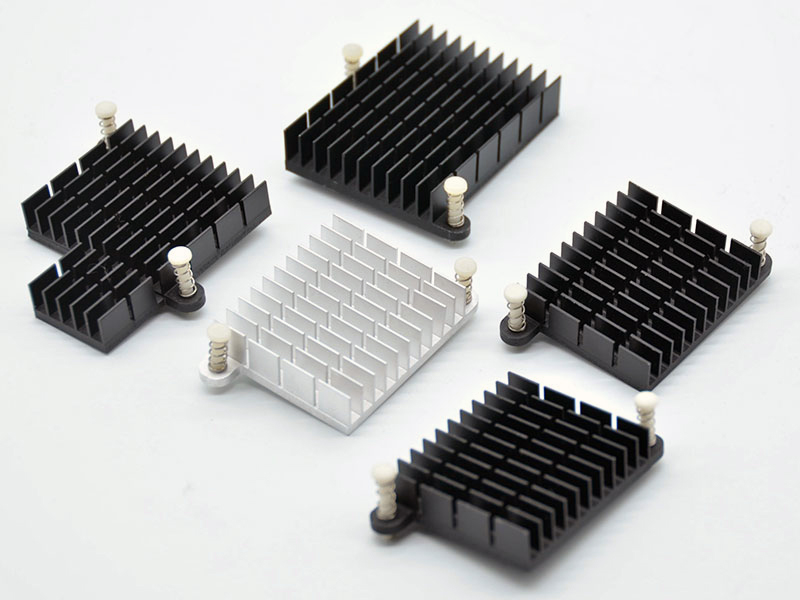

Motherboard Heatsinks

Customize Aluminum Heatsink

We offer different kind of heatsink manufacture depends on the need of our customers. Aluminum heat sink has high thermal conductivity and heat dissipation, it is a solution to effectively reduce thermal of the interface. It is designed to maximize its surface area in contact with the cooling medium surrounding it, such as the air. Air velocity, choice of material, protrusion design and surface treatment are factors that affect the performance of a heat sink.

CNC machining black anodized heatsinks

CNC machining black anodized heatsink , mainly used for motherboard. The grooved design of the surface...

DetailsH shaped heatsinks

CNC machining H shaped silver anodized heatsink, light and highly conductive thermal dissipation....

DetailsCNC machining silver anodized heatsinks

CNC machining anodized silver heatsinks for motherboard light and highly conductive thermal...

DetailsCNC machining gray anodized heatsinks with abbrasive.

Using CNC machining to ensure the flatness of the intersurface. External surface treatment...

DetailsCNC machinig ditched silver anodized heatsinks

Mainly used for the motherboard, the grooved design can increase the heat dissipation area.

DetailsHaving trouble dealing with aluminum manufacturing?

Contact us and we will provide solutions.

More DetailsMotherboard Heatsinks | ISO-Certified CNC Milling Services - Han Chang

Han Chang offers a wide range of CNC-machined aluminum part categories, including Motherboard Heatsinks, enclosures, heat sinks, brackets, and chassis components.

Our categories are tailored to serve EVs, industrial PCs, medical devices, and automation systems—all with ISO-certified quality.

We support custom designs, rapid prototyping, and full-scale OEM production for global manufacturers.