Aluminum chassis machining solution

experience of reducing aluminium machining deformation

Aluminum's soft-texture characteristics often cause deformation during extrusion porcess. For many years, we have been dealing deformation problems with our client from Germany, Japna, China, Turkey, USA, Korea and each client work in different industrial. However, one thing in common is the problem they face, aluminium 's deformation during machining process. And this is why they find us. Our 30 years experience help client overcome the issue that other can't do. The case below was issues we solved with our professional advice that our customer had with the other manufacturer. The product is now a regular order in mass production.Should you have any difficulty or question regarding aluminum processing, please fill out the contact us form and our team of experts will contact you as soon as possible.

Rectifying the deformation of aluminum chassis (U Shape)

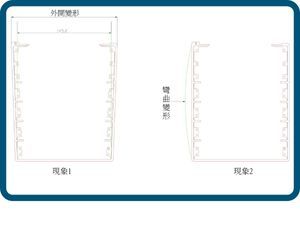

With this case, both sides of Aluminum RAID(Redundant Array of Independent Disks) of customer A are deformed due to its design. The U-shape design of the RAID chassis is very thin and thus caused 2 kinds of deformation during the making process - outward deformation and bending deformation. Customer A had a hard time finding the solution to overcome the assembling issue until they found us. With many years of experience, our team instantly found a way and suggested the customer re-tool the mold. Together with our shaping techniques customer A was able to assemble their product and sell on schedule.

Rectifying the deformation of aluminum chassis (square shape)

A IPC company needs an industrial data storage computer chassis which was deformed from square to parallelogram during the process of extrusion because of the high pressure.We found out this issue upon tryout of the mold, before the customer did. Our professional team instantly adjusted the operation process. By using our shaping techniques, we help customer B save a lot of time and lower the cost of product testing.

Having troubles with aluminium machining?

Give us a chance, Han Chang might be the answers.