Aluminium Prototypes & Product design

Aluminium metal working & sample making

Han Chang has devoted in the field of aluminum CNC milling that make us to do precise manufacturing and also perfect for rapid prototyping. We provide rapid sample making of aluminum computer cases and chassis, aluminum frames and aluminum front panels, electric vehicle parts. Our more than 30 years experienced mechanism design and capability of processing analysis striving to help our customers achieve the anticipated results, from aluminum extruded material (5052/6061/6063/7005/7075), aluminum surface treatment to the assembly of semi-finished products. Also, we offer chassis design and advising solutions for our customers to manufacture the perfect aluminum chassis, front panels, heatsinks that apply in the industrial field. In addition to CNC machining, sometimes we also use sheet metal bending procces to make prototypes for our clients.

Need Sampling in samll amount with a good deal?

- Benefits of sampling before tooling

- 1.Check for measuremet and construction.

- 2.Avoiding assembly erro because of engineering tolerance .

- 3.Reducing the risk of re-tooling or tooling modification.

Solution of aluminum chassis sample making-1

Company B has a need for aluminum chassis of audio devices, our team design an assembly aluminum chassis as shown in the following pictures. The aluminum enclosure has four parts including the top cover, bottom cover, front panel and the back panel. After confirmation of the drawing with the client, the fabrication process will be carried out from extrusion tooling which takes about 3-4 weeks, when the extrusion material is correctly made, we will start CNC machining, and brushing of the surface if needed before abrasive blasting or anodizing to make sure the surface is clean and flat. Finally, we print or laser marking company’s logo on the front panel as required

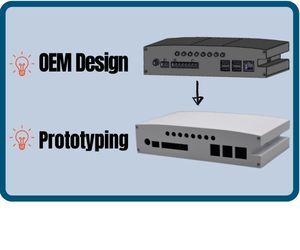

Solution of aluminum chassis sample making-2

Company C has a need for an aluminum chassis for communication and monitoring systems. They design and develop software but they need an enclosure which can dissipate the heat to lower the temperature of the device. After many times of communication and discussion, our team designed an aluminum chassis with base on the motherboard provided by the client. In order to dissipate the heat more efficiently, we suggested implanting a copper heat pipe in the back of the aluminum chassis. the fabrication process will be carried out from extrusion tooling which takes about 3-4 weeks, when the extrusion material is correctly made, we will start CNC machining, and brushing of the surface if needed before abrasive blasting or anodizing to make sure the surface is clean and flat. Finally, we print the company’s logo on the front panel as required.